QP Series ntawm Lub Tshuab Scraper Dryer

Yees duab

Lub tshuab ziab khaub ncaws nruas yog ib hom khoom siv ziab khaub ncaws uas tig thiab tig los ntawm lub cev, cov khoom ntub dej rau ntawm phab ntsa sab nraud ntawm lub nruas kom tau txais cov cua sov hloov pauv mus rau hauv daim ntawv ntawm cov cua sov, tshem tawm dej, kom ua tiav cov dej noo uas xav tau. Cov cua sov raug hloov los ntawm phab ntsa sab hauv mus rau phab ntsa sab nraud ntawm lub nruas, thiab tom qab ntawd los ntawm zaj duab xis khoom, nrog kev ua haujlwm thermal siab thiab kev ua haujlwm tas mus li, yog li nws yog siv dav hauv kev ziab cov khoom ua kua lossis cov khoom siv strip, thiab nws yog qhov tsim nyog dua rau cov khoom siv pasty thiab viscous.

Cov yam ntxwv

(1) Kev ua haujlwm kub siab:

Cov cua sov uas muab rau hauv lub tog raj kheej, ntxiv rau qhov me me ntawm cov hluav taws xob cua sov thiab qhov kawg ntawm lub hau ntawm lub cev lub tog raj kheej yog qhov poob cua sov, feem ntau ntawm cov cua sov yog siv rau hauv qhov ntub ntawm cov roj ua kom sov, qhov ua tau zoo ntawm cov cua sov tuaj yeem siab txog 70 ~ 80%.

(2) Qhov ziab sai heev:

Cov txheej txheem hloov cua sov thiab pawg ntawm cov zaj duab xis ntub dej ntawm phab ntsa lub tog raj kheej, los ntawm sab hauv mus rau sab nraud, hauv tib qho kev coj ua, qhov kub thiab txias gradient loj, yog li cov khoom zaj duab xis nto kom tswj tau qhov siab evaporation zog, feem ntau txog li 30 ~ 70kg.H₂O / m².h.

(3) Qhov zoo ntawm cov khoom kom qhuav yog ruaj khov:

Hom cua sov rau cov menyuam yaus yooj yim tswj, qhov kub thiab txias hauv lub tog raj kheej thiab qhov hloov pauv cua sov ntawm phab ntsa tuaj yeem khaws cia kom ruaj khov, yog li cov khoom siv zaj duab xis tuaj yeem qhuav hauv qhov ruaj khov ntawm kev hloov pauv cua sov, thiab qhov zoo ntawm cov khoom tuaj yeem lav.

(4) Ntau yam kev siv:

Cov khoom siv ua kua theem siv lub nruas ziab, yuav tsum muaj kev txav mus los, kev nplaum thiab thermal stability ntawm daim ntawv ntawm cov khoom siv tuaj yeem ua cov kua, tsis sib xws suspension, emulsion, sol-gel thiab lwm yam. Rau pulp, textiles, celluloid thiab lwm yam ntaub ntawv band kuj siv tau.

(5) lub peev xwm tsim khoom ntawm ib lub tshuab:

Txwv los ntawm qhov loj ntawm lub tog raj kheej. Feem ntau lub tshuab ziab khaub ncaws yuav tsum tsis txhob loj dhau. Lub cheeb tsam ziab ntawm ib lub tog raj kheej, tsis tshua muaj ntau tshaj 12 m2. Cov lus qhia ntawm cov khoom siv zoo ib yam, muaj peev xwm ua haujlwm nrog cov kua, tab sis kuj los ntawm qhov xwm txheej ntawm cov kua, kev tswj cov dej noo, zaj duab xis tuab, qhov ceev ntawm lub nruas thiab lwm yam, qhov loj ntawm kev hloov pauv loj, feem ntau nyob rau hauv ntau ntawm 50 txog 2000kg / h. Lub cheeb tsam ziab ntawm ib lub tog raj kheej, tsis tshua muaj ntau tshaj 12 m2.

(6) cua sov nruab nrab yog yooj yim:

Feem ntau siv cov pa dej uas muaj roj ntau, qhov siab ntawm 2 ~ 6kgf / com2, tsis tshua muaj ntau tshaj 8kgf / cm2. Rau qee qhov xav tau ntawm kev ziab cov khoom siv ntawm qhov kub qis, dej kub tuaj yeem siv ua cov khoom siv cua sov: kom ziab cov khoom siv ntawm qhov kub siab dua, kuj tseem siv tau ua cov khoom siv cua sov lossis cov organic uas kub heev ua cov khoom siv cua sov.

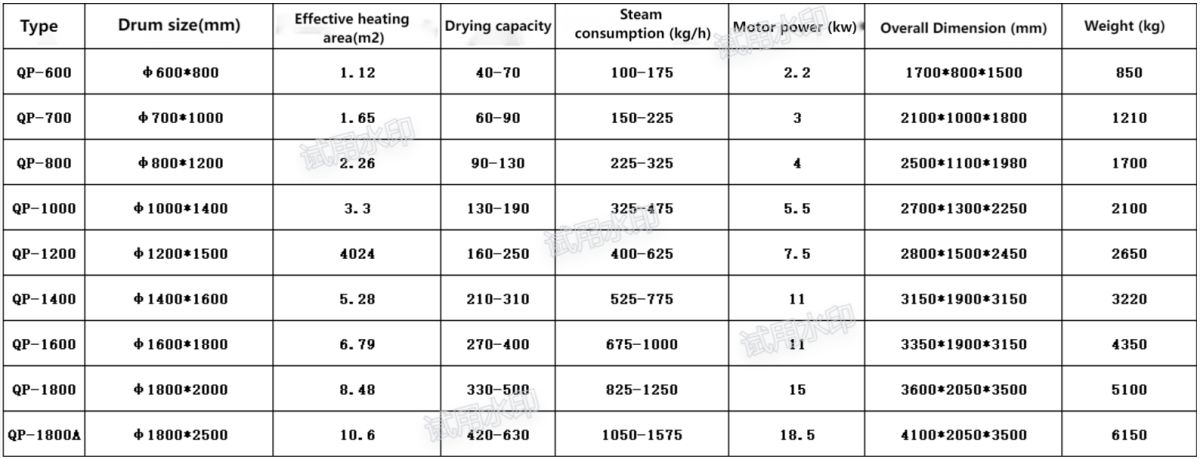

Daim Ntawv Qauv

Lub tshuab ziab khaub ncaws siv lub nruas tuaj yeem muab faib ua ob hom: ib lub tog raj kheej, ob lub tog raj kheej. Tsis tas li ntawd xwb, nws kuj tseem tuaj yeem muab faib ua ob hom kev siab ib txwm thiab kev txo qis raws li kev ua haujlwm siab.

Kev teeb tsa

Raws li qhov kev teeb tsa dav dav ntawm lub tshuab ziab khaub ncaws, lub hauv av yuav tsum tiaj tus, qhov nkag ntawm cov kav dej yuav tsum tau teeb tsa lub ntsuas siab thiab lub qhov cua nyab xeeb, lub flange nkag ntawm cov kav dej txuas ruaj khov.

Cov cheeb tsam siv

Yancheng City Quanpin Machinery Drying Drum Scraper Dryer feem ntau yog siv los daws cov khoom siv kua, uas tuaj yeem ua kom sov thiab ziab los ntawm cov pa dej, dej kub lossis roj kub, thiab txias thiab khi los ntawm dej txias: nws tuaj yeem siv raws li qhov xwm txheej ntawm cov ntaub ntawv sib txawv thiab cov kev xav tau thev naus laus zis, xws li kev raus dej, txau, milling thiab lwm txoj hauv kev them.

Kev hloov kho cov ntaub ntawv

Lub tshuab ziab khaub ncaws nruas yog qhov tsim nyog rau kev ziab cov kua lossis cov khoom siv viscous ntau dua hauv kev lag luam tshuaj lom neeg, lub tshuab lim dej, tooj liab sulphate, kua nplaum tsiaj, kua nplaum cog, cov poov xab zas xim, cov tshuaj tua kab mob, lactose, hmoov txhuv nplej siab slurry, sodium nitrite, dyestuff, distillation pov tseg kua, sulphide xiav, penicillin dregs, cov protein rho tawm dej khib nyiab, metallurgy thiab lwm yam lag luam.

Kev Txij Nkawm

1) Tsis tu ncua xyuas qhov kev hloov pauv ntawm cov khoom tig, seb puas muaj qhov tshwm sim jamming. Sprocket thiab lwm qhov yuav tsum tau ntxiv rau hauv cov roj, kho qhov yuam kev ntawm cov ntsuas siab thiab lwm yam khoom siv ntsuas. Cov khoom siv tsav tsheb daim duab peb sab yuav tsum tau hloov pauv raws sijhawm yog tias muaj kev hnav thiab tsim kua muag loj.

2) Kev saib xyuas lub cev muaj zog thiab lub tshuab txo qis tau qhia nyob rau hauv phau ntawv qhia ntawm lub cev muaj zog thiab lub tshuab txo qis.

Kho Cov Cheebtsam Thaum Lub Sijhawm Ntsuas

1) Lub tshuab ziab khaub ncaws ib lub nruas yuav tsum tau sim tom qab kev teeb tsa los ntawm kev pib lub cev muaj zog tseem ceeb thiab saib lub nruas tseem ceeb tig kom raug.

2) Saib xyuas lub nruas tseem ceeb thiab kev sib hloov ntawm cov khoom sib kis tau yooj ywm, saib xyuas qhov kev xa tawm thiab xa tawm ntawm cov pa dej txuas nrog, seb lub ntsuas siab puas nyob hauv qhov ntau ntawm kev ua haujlwm siab.

3) pib lub cev muaj zog, lub nruas tseem ceeb khiav zoo, qhov kub nce tom qab koom nrog cov khoom siv los kho qhov ceev ntawm lub cev muaj zog thiab cov khoom siv ntawm zaj duab xis nruas kom tswj tau cov dej noo kawg ntawm cov khoom siv.

4) Pib lub tshuab winch, tso tawm cov khoom qhuav tiav, raws li qhov ntau ntawm cov khoom qhuav tiav los kho qhov ceev ntawm lub tshuab winch.

QUANPIN Lub Tshuab Ziab Khaub Ncaws Granulator

YANCHENG QUANPIN MACHINERY CO., LTD.

Ib lub chaw tsim khoom tshaj lij uas tsom mus rau kev tshawb fawb, kev txhim kho thiab kev tsim khoom siv ziab khaub ncaws, cov khoom siv granulator, cov khoom siv sib tov, cov khoom siv crusher lossis cov khoom siv sieve.

Tam sim no, peb cov khoom tseem ceeb suav nrog lub peev xwm ntawm ntau hom kev ziab, granulating, crushing, sib tov, concentrating thiab extracting khoom siv ncav cuag ntau dua 1,000 teeb tsa. Nrog kev nplua nuj kev paub thiab kev ua haujlwm zoo.

https://www.quanpinmachine.com/

https://quanpindrying.en.alibaba.com/

Xov Tooj Ntawm Tes: +86 19850785582

WhatsApp: +8615921493205