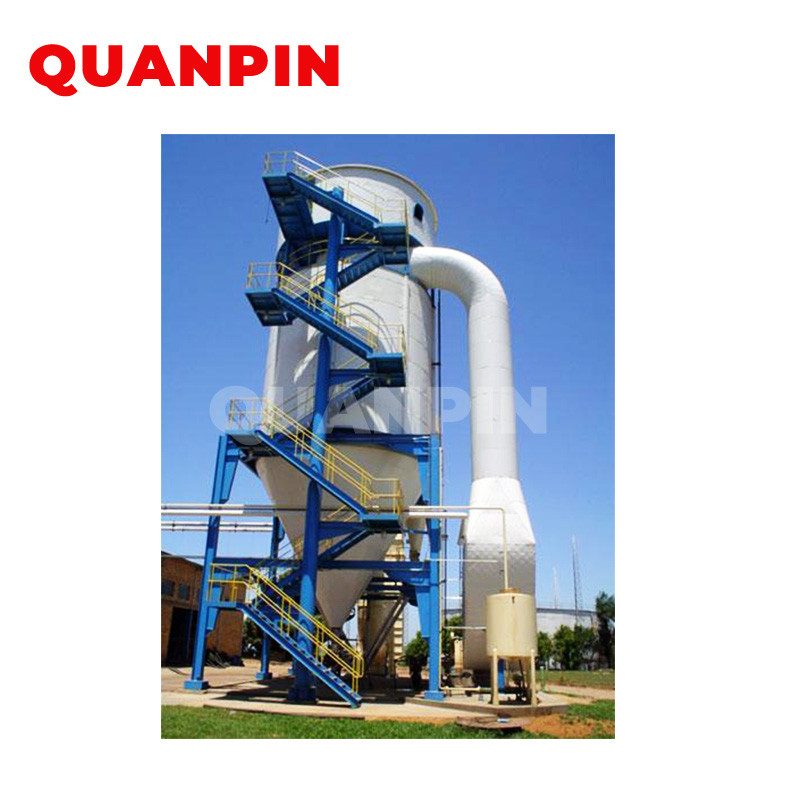

LPG Series High-Speed Centrifugal Tsuag Tshuab Ziab Khaub Ncaws Nrog Tus Nqi Loj

Cov lus piav qhia

Kev siv tshuaj tsuag ziab yog cov thev naus laus zis siv dav tshaj plaws hauv kev tsim cov kua thiab hauv kev lag luam ziab. Cov thev naus laus zis ziab no zoo tshaj plaws rau kev tsim cov hmoov khov lossis cov khoom me me los ntawm cov khoom siv kua, xws li: cov kua, emulsion, suspension thiab cov tshuaj nplaum uas nqus tau, vim li no, thaum qhov loj me thiab kev faib tawm ntawm cov khoom kawg, cov dej seem, qhov ceev ntawm cov khoom thiab cov duab ntawm cov khoom me me yuav tsum ua tau raws li tus qauv meej, kev ziab tshuaj tsuag yog ib qho ntawm cov thev naus laus zis xav tau tshaj plaws.

Yees duab

Txoj Cai Ua Haujlwm

Lub tshuab tsuag qhuav rau lub voj voog qhib thiab ntws, centrifugal atomization. Tom qab cua qhuav nruab nrab thaum ntxov, cov lim cua nruab nrab thiab lim raws li cov lus qhia ua haujlwm los ntawm kev rub thiab tom qab ntawd cua sov los ntawm lub tshuab cua sov lim dej zoo los ntawm kev nkag mus rau hauv lub tshuab cua kub dispenser tsuag kom qhuav lub pej thuam loj. Tom qab cov khoom ua kua raws li cov lus qhia ua haujlwm peristaltic twj tso kua mis, atomizer mus rau hauv qhov tig ceev ceev, lub zog centrifugal raug faib ua cov tee me me. Hauv lub tshuab tsuag qhuav lub pej thuam loj nrog cua kub hauv cov tee me me sib cuag tag nrho ziab los ntawm kev sib pauv cua sov nrog cov khoom raws txoj kev tshwj xeeb, tom qab ntawd los ntawm lub voj voog kom ua tiav kev sib cais, cov khoom khov kho raug sau, lim thiab tom qab ntawd cov pa roj, thiab tom qab ntawd tso tawm. Tsuag tag nrho lub kaw lus yooj yim ntxuav, tsis muaj qhov kawg tuag, ua raws li GMP cov cai.

Cov Ntsiab Lus:

1. Kev sib cuag nrog cov cua kub poob: kom txaus cua kub nkag mus rau hauv chav ziab kom qhuav yuav tsum tau xav txog qhov kev taw qhia thiab lub kaum sab xis ntawm cov pa kub ntws, thiab seb nws yog ntws, ntws rov qab lossis ntws sib xyaw, kom ntseeg tau tias kev sib cuag tag nrho nrog cov dej poob tuaj yeem sib pauv cua sov txaus.

2. Tshuaj tsuag: Lub tshuab tsuag tshuab ziab khaub ncaws yuav tsum ua kom muaj qhov sib npaug ntawm cov tee dej, uas yog qhov tseem ceeb. Vim tias yuav kom ntseeg tau tias qhov nrawm ntawm cov khoom zoo.

3. Thiab lub kaum sab xis ntawm lub kaum sab xis ntawm lub raj xa dej: Peb tau txais qee cov ntaub ntawv los ntawm kev tsim khoom ntawm ze li ntawm ib txhiab units Spray Dryer pawg, thiab peb tuaj yeem sib qhia.

Nta:

1. Kev txau kom qhuav sai, thaum cov kua dej raug atomized, thaj chaw ntawm cov khoom nce ntxiv ntau, nrog rau cua kub sib cuag nrog cov txheej txheem, lub sijhawm tuaj yeem yog 95% -98% dej noo evaporation, lub sijhawm ziab tsuas yog ob peb feeb xwb, tshwj xeeb tshaj yog rau cov khoom siv cua sov-rhiab kom qhuav.

2. Cov khoom muaj kev sib npaug zoo, muaj zog dua thiab solubility, purity thiab zoo.

3. Cov txheej txheem tsim cov tshuaj tsuag ziab yog yooj yim, yooj yim rau kev tswj hwm. Rau cov dej noo ntawm 40-60% (rau cov khoom tshwj xeeb, txog li 90%) ntawm cov kua tuaj yeem ziab ua cov khoom hmoov, tom qab ziab yam tsis muaj kev sib tsoo thiab kev tshuaj ntsuam kom txo cov txheej txheem tsim khoom, txhim kho cov khoom huv. Rau qhov loj me, qhov ceev ntawm cov khoom, dej noo, hauv qee qhov ntau yam tuaj yeem hloov kho los ntawm kev hloov pauv cov xwm txheej ua haujlwm, kev tswj hwm thiab kev tswj hwm yooj yim heev.

Kev Ntsuas Txuj Ci

| Qauv/Khoom | 5 | 25 | 50 | 100 | 150 | 200 | 500 | 800 | 1000 | 2000 xyoo | 3000 | 4500 | 6500 | ||

| Qhov kub ntawm huab cua nkag (°C) | 140-350 Kev Tswj Xyuas Tsis Siv Neeg | ||||||||||||||

| qhov kub thiab txias ntawm huab cua (°C) | 80-90 | ||||||||||||||

| Txoj kev ua kom atomizing | Kev kub ceev centrifugal atomizer (mechanical kis tau tus mob) | ||||||||||||||

| Kev ua pa dej qhov siab tshaj plaws (kg/h) | 5 | 25 | 50 | 100 | 150 | 200 | 500 | 800 | 1000 | 2000 xyoo | 3000 | 4500 | 6500 | ||

| Kev ceev siab tshaj plaws (rpm) | 25000 | 22000 | 21500 | 18000 | 16000 | 12000-13000 | 11000-12000 | ||||||||

| Lub taub hau ntawm lub phaj tsuag (hli) | 60 | 120 | 150 | 180-210 | Raws li qhov xav tau ntawm cov txheej txheem kev ua haujlwm | ||||||||||

| qhov chaw kub | Hluav taws xob | pa + hluav taws xob | Ncu + hluav taws xob, roj roj, roj av, qhov cub tawg kub | ||||||||||||

| Lub zog cua sov hluav taws xob qhov txwv siab tshaj (kw) | 12 | 31.5 | 60 | 81 | 99 | Siv lwm qhov chaw cua sov | |||||||||

| Qhov Loj (L × W × H) (m) | 1.6 × 1.1 × 1.75 | 4 × 2.7 × 4.5 | 4.5 × 2.8 × 5.5 | 5.2 × 3.5 × 6.7 | 7 × 5.5 × 7.2 | 7.5 × 6 × 8 | 12.5 × 8 × 10 | 13.5 × 12 × 11 | 14.5 × 14 × 15 | Txiav txim siab raws li qhov xwm txheej tiag tiag | |||||

| Cov khoom hmoov tus nqi rov zoo | Kwv yees li 95% | ||||||||||||||

Luv luv

Lub Tshuab Ziab Khaub Ncaws, Lub Tshuab Ziab Khaub Ncaws yog cov txheej txheem ua kua thiab kev lag luam ziab khaub ncaws yog qhov siv dav tshaj plaws. Zoo tshaj plaws rau kev tsim cov hmoov los ntawm cov tshuaj emulsions, cov tshuaj, emulsions thiab cov kua nplaum, cov khoom khov granular. Yog li, thaum cov khoom tiav lawm qhov loj me ntawm cov khoom me me, cov dej noo seem, qhov ceev ntawm cov khoom loj thiab cov duab ntawm cov khoom me me sib xws nrog tus qauv tseeb, Lub Tshuab Ziab Khaub Ncaws yog qhov zoo tagnrho rau cov txheej txheem ziab khaub ncaws.

Daim Ntawv Qhia Txog Kev Ua Haujlwm

Daim Ntawv Thov

Cov khoom siv tshuaj lom neeg: PAC, disperse dyes, reactive dyes, organic catalysts, silica, hmoov ntxhua khaub ncaws, zinc sulfate, silica, sodium silicate, potassium fluoride, calcium carbonate, potassium sulfate, inorganic catalysts, txhua yam thiab lwm yam pov tseg.

Khoom noj: amino acids, vitamins, qe, hmoov nplej, pob txha hmoov, txuj lom, protein, mis hmoov, ntshav hmoov, taum pauv hmoov, kas fes, tshuaj yej, glucose, potassium sorbate, pectin, tsw qab thiab tshuaj tsw qab, kua zaub, poov xab, hmoov txhuv nplej siab, thiab lwm yam.

Cov Khoom Siv Ua Los Ntawm Av nplaum: Alumina, zirconia, magnesia, titania, titanium, magnesium, kaolin, av nplaum, ntau yam ferrites thiab hlau oxides.

QUANPIN Lub Tshuab Ziab Khaub Ncaws Granulator

YANCHENG QUANPIN MACHINERY CO., LTD.

Ib lub chaw tsim khoom tshaj lij uas tsom mus rau kev tshawb fawb, kev txhim kho thiab kev tsim khoom siv ziab khaub ncaws, cov khoom siv granulator, cov khoom siv sib tov, cov khoom siv crusher lossis cov khoom siv sieve.

Tam sim no, peb cov khoom tseem ceeb suav nrog lub peev xwm ntawm ntau hom kev ziab, granulating, crushing, sib tov, concentrating thiab extracting khoom siv ncav cuag ntau dua 1,000 teeb tsa. Nrog kev nplua nuj kev paub thiab kev ua haujlwm zoo.

https://www.quanpinmachine.com/

https://quanpindrying.en.alibaba.com/

Xov Tooj Ntawm Tes: +86 19850785582

WhatsApp: +8615921493205